P4 – Fragmentation in Large Scale DEM Simulations

Motivation

Motivation

During the past decade, the technique of Discrete Element Simulations (DEM) made great progress and by now it is generally acknowledged as a reliable tool for bulk solids description in a variety of applications [1], [2]. There is a number of models available in the literature to describe fragmentation of particles in DEM [3], [4] simulations, however, by now the predictive power of these models is still poor, especially when dealing with fragmentation probabilities and fragment size distribution. Current approaches use purely spherical models and there is still a gap in predictive fragmentation models for non-spherical particles.

Objectives

The aim of the present research project is to develop a particle model which allows for both realistic modelling of fragmentation in DEM simulations and at the same time highly efficient large scale simulations.

Work plan

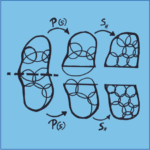

To enable large scale DEM simulations with realistic modelling of fragmentation we will proceed with i) perform full 3d simulations of non-spherical particles using a multi-sphere [5] approach; ii) statistically correct the load dependent fragmentation probabilities and fragment size distribution, in agreement with empirical laws; iii) modelling of wear (ageing) trough incorporation of micro-crack modelling using a variant of bonded particle description [3], in agreement with empirical laws and with micro-mechanical (atomistic) simulations performed in the RTG; iv) correct representation of particle-size dependent fragmentation properties through a hierarchical multi-sphere representation of particles and fragments using multi-scale descriptions. The derived particle model shall be incorporated to a DEM environment like Liggghts [6]. We expect to be able to simulate systems of typically 105 non-spherical particles over process-relevant times. As a benchmark for the predictive power and the efficiency of the model we plan to simulate milling processes and compare the results with experimental results available in the literature.

[1] H. P. Zhu, Z. Zhou, R. Yang and A. Yu, “Discrete particle simulation of particulate systems: Theoretical developments,” Chemical Engineering Science, vol. 62, pp. 3378-3396, 2007.

[2] N. Gunkelmann, M. Montaine and T. Pöschel, “Stochastic behavior of the coefficient of normal restitution,” PHYSICAL REVIEW E, vol. 89, p. 022205, 2014.

[3] D. Potyondy and P. Cundall, “A bonded-particle model for rock,” International Journal of Rock Mechanics and Mining Sciences, vol. 41, pp. 1329-1364, 2004.

[4] T. Pöschel and T. Schwager, Computational Granular Dynamics, Springer-Verlag Berlin Heidelberg, 2005.

[5] E. J. R. Parteli and T. Pöschel, “Particle-based simulation of powder application in additive manufacturing,” Powder Technology, vol. 288, pp. 96-102, 2016.

[6] C. Kloss, C. Goniva, A. Hager, S. Amberger and S. Pirker, “Models, algorithms and validation for opensource DEM and CFD-DEM,” Progress in Computational Fluid Dynamics, An International Journal, Vols. 12, No.2/3, pp. 140-152, 2012.