P3 – Fracture in Polymer Composites: Nano to Meso

Motivation

Motivation

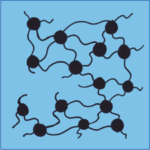

The abrasion and fracture toughness of polymers can considerably be increased by adding hard nanoparticles such as silica [1], [2]. This is mainly caused by the development of localized shear bands, initiated by the stress concentrations stemming from the inhomogeneity of the composites. Other mechanisms responsible for toughening are debonding of the particles and void growth in the polymer matrix. Both phenomena strongly depend on the structure and chemistry of the polymers and shall be explored for branched networks (epoxy) and matrices of nestled fibres (cellulose, aramid).

Objectives

The goal of the present project is to develop and apply dynamics simulation approaches to understanding polymer-nanoparticle and polymer-polymer interactions at i) the atomic scale and ii) at larger scales using coarse-graining.

Work plan

i) molecular dynamics simulations shall elaborate detailed insights into polymer-nanoparticle association and dissociation. Moreover, atomistic models are used to analyse the inorganic-organic interfaces of composites, their rearrangement upon plastic deformation, and nanoparticle-polymer debonding during fracture nucleation and growth [3]. Using such molecular scale understanding of damaging and fracture mechanisms, we furthermore ii) outlined a coarse-graining strategy to access larger length scales. Therein, we maintain the focus on particle-based models to account for the local inhomogeneity of the composite material by coarsening nanoparticles and polymer networks into single or chains of particles, respectively [3], [4]. The interaction potentials for the molecular simulations i) were derived from quantum calculations, and thus require no parameterization from experiment. Similarly, ii) the envisaged model coarsening is fully based on the findings from the atomic scale. Comparison to the experiment may hence entirely be used for validation of our work. Moreover, linking meso- to macro scale simulations based on empirical models (such as advanced finite element approaches) to the particle-based models of the present model could allow the molecular-level interpretation of mechanical properties observed at the macro-scale.

[1] T. Hsieh, A. Kinloch, K. Masania, A. Taylor and S. Sprenger, “The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles,” Polymer, vol. 51, no. 26, pp. 6284-6294, 2010.

[2] Y. F. Chen and R. C. C. B. Lam, “Reibbelagmaterialien”. DE Patent 69515938 T3, 9 2005.

[3] D. Zahn, “A Molecular Rationale of Shock Absorption and Self-Healing in a Biomimetic Apatite–Collagen Composite under Mechanical Load,” Angewandte Chemie International Edition, vol. 49, no. 49, pp. 9405-9407, 2010.

[4] D. Zahn and P. Duchstein, “Multi-Scale Modelling of Deformation and Fracture in a Biomimetic Apatite-Protein Composite: Molecular-Scale Processes Lead to Resilience at the μm-Scale,” PLOS ONE, vol. 11, no. 6, pp. 1-8, 2016.